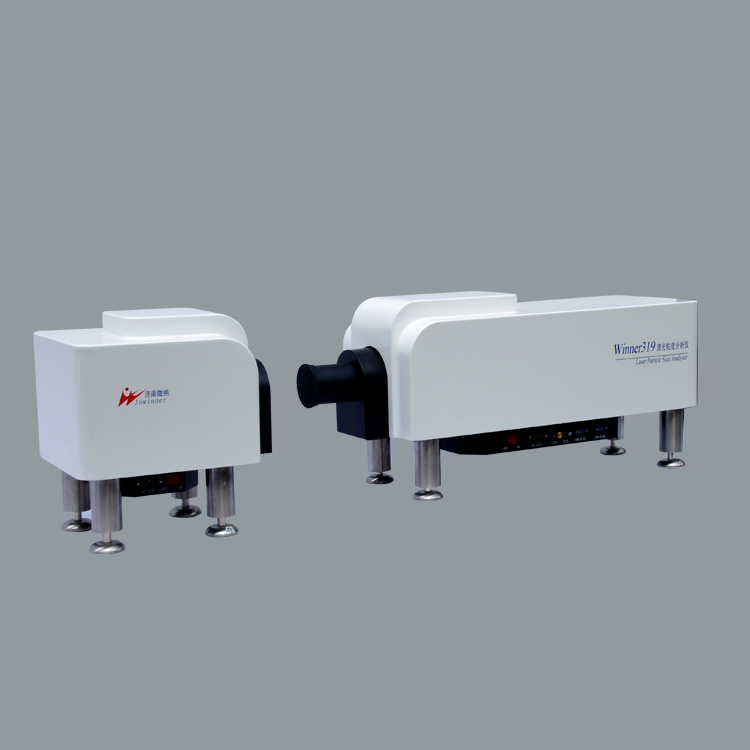

Winner3009 Dry Laser Particle Sizer (intelligent)

Winner3009 is an intelligent dry process laser particle size analyzer and the fifth generation new product of the company. Winner3009 has mature technology, stable operation and advanced testing principle. It uses turbulent dispersion patented technology and positive shock wave shear technology to fully disperse particles and ensure the stability and accuracy of particle testing results.

Keyword:

Category:

Dry laser particle sizer

E-mail:

Winner3009 Dry Laser Particle Sizer (intelligent)

Product introduction:

Winner3009 is an intelligent dry process laser particle size analyzer and the fifth generation new product of the company. Winner3009 has mature technology, stable operation and advanced testing principle. It uses turbulent dispersion patented technology and positive shock wave shear technology to fully disperse particles and ensure the stability and accuracy of particle testing results.

Product advantages:

Integration of multiple technologies and advanced testing principles

The convergent Fourier transform optical path and the bispectral optical path are used to overcome the limitation of the lens aperture on the scattering angle, and enhance the identification and test stability of submicron particles.

Proprietary patented decentralized technology

The turbulent dispersion patented technology (Patent No.: zl.2 0072 0018648.7) and the positive shock wave shear technology are adopted to fully disperse the particle samples in the air to ensure the accuracy of the test. The key components of the dispersion system adopt wear-resistant ceramics to improve the service life of the products.

Spectrum amplification technology

By enhancing the sensitivity of the probe to the signal, it can effectively accept the scattered light signals of various angles corresponding to the test range, and the detection angle is 0.0155-164 degrees, which improves the test range and accuracy of the instrument.

Intelligent operation

Click the "automatic test" button, and all operation processes of the instrument, including feeding, gas supply and dust collection, will be completed automatically.

Intelligent data processing

The instrument analysis software collects a large amount of grain size information data at high speed, inverts the grain size distribution through unconstrained free fitting, and then intelligently counts and processes the test data to ensure the accuracy and stability of the output results.

Previous

Nothing

Next

MESSAGES