Winner7000 series universal online particle size analyzer

The on-line particle size detection system for powder production is an indispensable device to improve product quality, reduce power consumption, increase output and improve the automation level of production. Jinan Weina company has carried out a number of research work on laser particle size analyzer for on-line monitoring for a long time and achieved remarkable results.

Keyword:

Category:

On line particle sizer

E-mail:

Winner7000 series universal online particle size analyzer

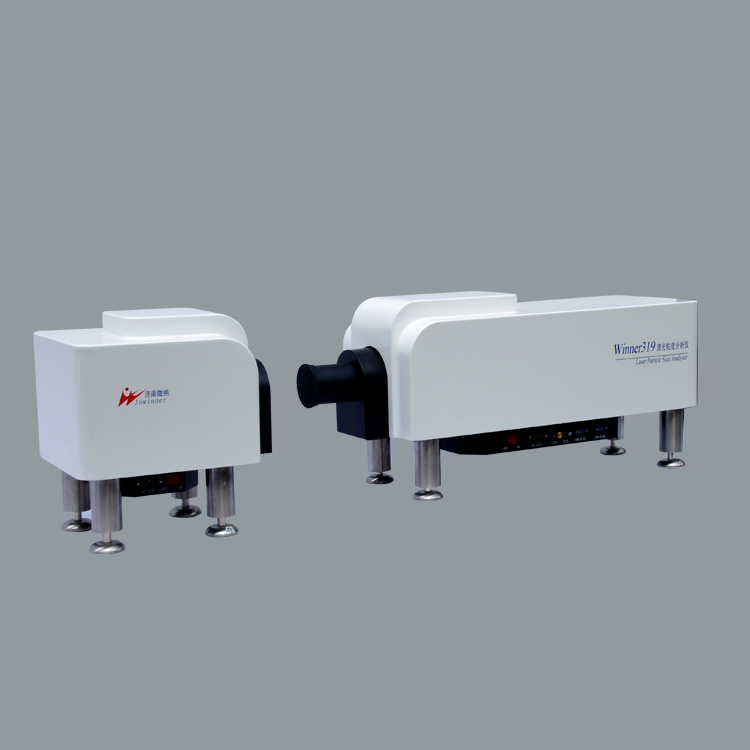

Universal online particle size analyzer

The on-line particle size detection system for powder production is an indispensable device to improve product quality, reduce power consumption, increase output and improve the automation level of production. Jinan Weina company has carried out a number of research work on laser particle size analyzer for on-line monitoring for a long time and achieved remarkable results.

Using Mie scattering principle, this product can monitor the particle size distribution of flowing particles in real time, and provide various particle size data concerned by customers. It is a reliable assistant for enterprises to save energy and reduce consumption.

Product advantages

1. good versatility: modular design, flexible combination of sampler, test host and other components, suitable for a variety of site conditions, and applicable to a variety of industrial production site conditions

2. wide application: widely used in carbon, building materials, chemical industry, abrasive and other industries.

3. high data accuracy: due to the use of automatic sampling and automatic testing, the human error is minimized, and the testing accuracy is much higher than that of offline testing or screening and other manual testing methods.

4. strong real-time data: grasp the production situation at any time and effectively reduce the generation of nonconforming product batches.

5. good durability: the structure design is reasonable, and has the functions of power failure protection, shutdown protection, automatic cleaning, etc., which is suitable for long-term maintenance free use.

6. automatic material return to avoid waste: after the material test, it can automatically return to the production line or transportation pipeline without wasting materials.

7. standard data interface, which can connect DCS or PLC with other equipment to realize unattended.

Conceptual design

1. design principle: Mie scattering theory (laser method is the most widely used test method at present, and the test accuracy and stability are very good)

2. complete machine structure: split type (more flexible installation and stronger versatility)

3. sampling method: mechanical / pneumatic / venturi (multiple sampling methods are available, suitable for most factory environments)

4. return mode: mechanical / pneumatic / self return (multiple return modes, suitable for most factory environments)

5. dispersion mode: turbulent dispersion (ensuring the dispersion effect, making it cleaner and convenient for material recovery)

6. lens protection: air curtain type

7. cleaning method: regular cleaning with high-pressure air

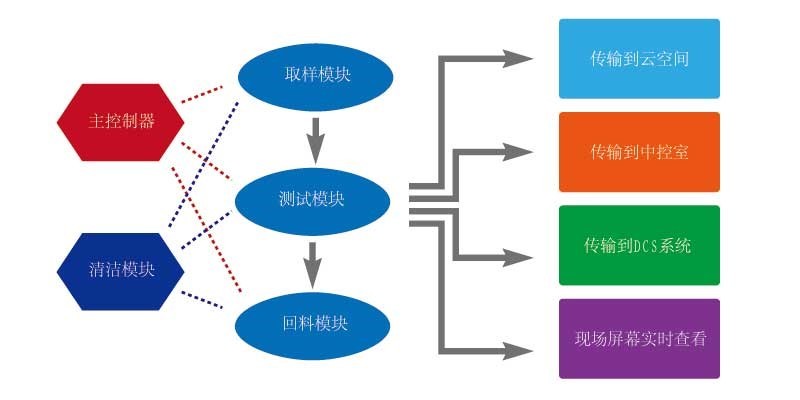

Structure legend

1. sampling module: automatic continuous or periodic sampling from the user's production line,

2. test module: test the samples taken. The test results as shown in the figure can be viewed in real time on the site screen, or transmitted to the DCS system to further realize advanced industrial control. It can also be transmitted to the central control room and cloud space for customers to monitor anytime and anywhere.

3. material return module: the tested samples shall be returned to the production line to eliminate waste.

4. main controller: uniformly control the sampling module, test module and return module to ensure their coordinated operation.

5. cleaning module: clean and protect the sampling module, test module and return module to ensure their long-term stable operation.

Previous

Nothing

Next

MESSAGES